RFID

What is RFID?

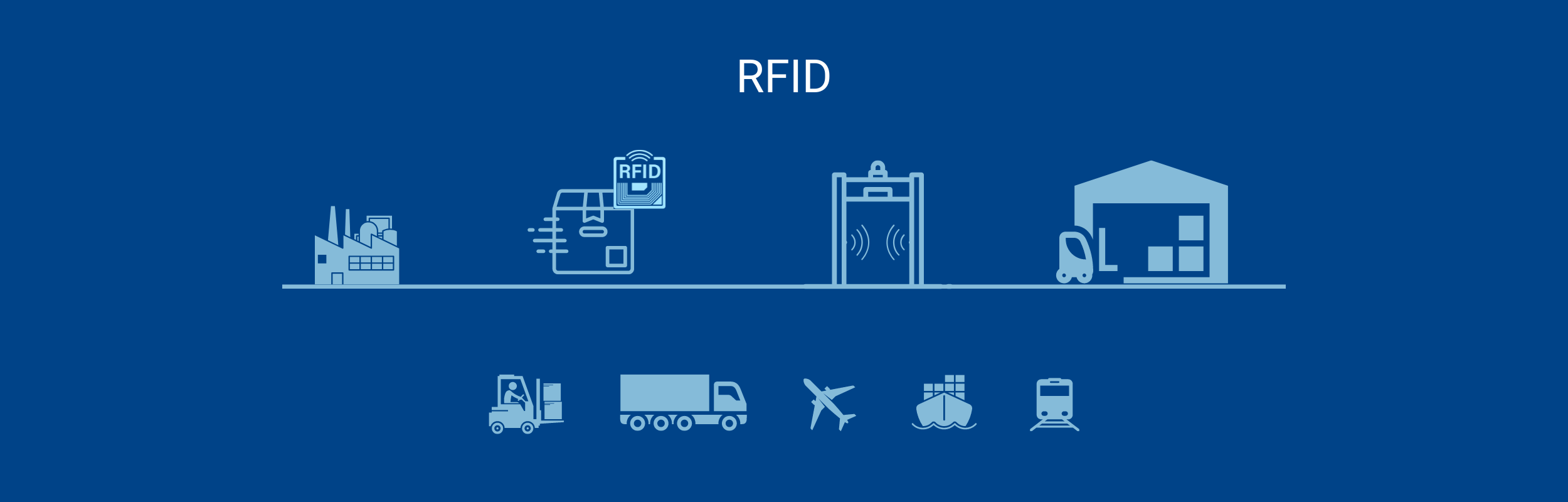

Every company is keen to improve supply chain processes and maintain control over the goods it ships. Logistics companies and manufacturers are therefore always looking for new technologies that make it possible to seamlessly monitor and document the transport conditions of their goods throughout the entire supply chain. RFID technology provides companies with a cost-effective solution for monitoring transport and improving inventory control within a warehouse. The application of an RFID system is very simple:

Typical RFID tracking systems consist of a transponder containing an identifying code and a reader to read the identifier. The RFID label, which is attached to the goods themselves or to the parcel, can be used to determine where an object is located at any given time. In this way, goods can be localised and the environmental conditions tracked - for example in the warehouse or during transport. If conditions occur that could cause damage to the product, RFID devices trigger an alarm. RFID solutions are so flexible that they can be easily integrated into an existing ERP system and thus ensure greater transparency within the supply chain.

Effective transport monitoring and warehouse logistics with RFID

Our RFID products in the shop

- RFID-enabled shock indicator

- Enables contactless detection of triggered indicators

- Shock sensitivities from 5g to 75g

- Activation on attachment

- No battery or cable required

- Operating temperature range -25°C to 60°C / -13°F to 140°F